An Italkrane Overhead Travelling Crane in futuristic hydrogen train maintenance facility

The brand-new hydrogen train maintenance workshop in Rovato (BS) will

Italkrane, founded in 1962, has established itself as an international point of reference in the design and construction of explosion-proof lifting equipment and transportation.

Our products are entirely Made in Italy, and our models are the result of creativity and engineering.

In particular, we are recognized for our expertise and proven experience in the construction of explosion-proof machinery for petrochemical plants in hazardous atmospheres.

Italkrane, with over 60 years of experience, offers custom solutions for lifting and logistics, combining innovation and Italian high engineering tradition. The company is highly customer-oriented, aiming to create long-lasting relationships with customers and guarantee the highest quality standards in every product.

Our experienced team of technicians and engineers support customers throughout all the stages of equipment and machinery development and manufacturing.

We are global leaders in the lifting solutions market, with an extensive international presence, and recognized quality in terms of products and services.

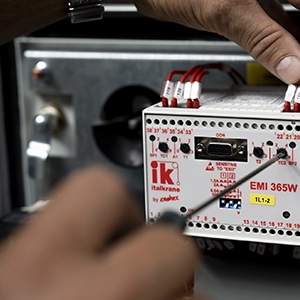

Ariet is a small company with over 60 years of experience in supplying certified explosion-proof components for lifting systems. In particular, it specializes in explosion-proof products for use in hazardous atmospheres, with flammable dust and gases.

We are working to expand our global presence and reach new markets.

The company Italkrane S.r.l. was established with the aim of designing, manufacturing and marketing a wide range of lifting and transport equipment and machinery, designed for various dimensions, loads, capacities and types of materials.

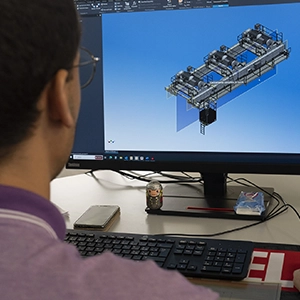

Our Design Office helps our customers find the perfect solution to their specific needs. Our team of skilled engineers is at your complete disposal.

The production phase of Italkrane is a highly specialized process where ideas take shape and lifting and transportation equipment and machinery are created with great precision and attention to detail.

Italkrane offers a personalized Consultancy Service, bringing competence and dedication to the table, to help you achieve excellence and success for your company.

Italkrane’s After-sales Service is synonymous with commitment and reliability. Our complete and timely support guarantees that your lifting and transport equipment will maintain maximum performance over time, bringing you the confidence of a

long-lasting partnership.

Italkrane has consistently pursued the objectives of quality and safety in all its activities.

Stay up to date on the latest news in the world of explosion-proof lifting and transport equipment.

The brand-new hydrogen train maintenance workshop in Rovato (BS) will

The Angola NGC Phase 1 Project is a green field

INEOS and TECNICAS REUNIDAS awarded to Italkrane the Purchase Order

For more information, please do not hesitate to contact us directly.

We’re here to help you!

Monday to Friday:

8.30 am to 12.30 pm and 1.30 pm to 5.30 pm

Saturday and Sunday: closed.

LEADER IN THE DESIGN PRODUCTION OF EXPLOSION-PROOF LIFTING EQUIPMENT

© Via Monza, 13 20041 Bussero (Milan – Italy) – P. IVA 00868460155 – Tel +39 02 929 721 – Fax +39 02 950 34 16 – Email: italkrane@italkrane.it